2,4,5-Trifluorophenylacetic acid Chemische Eigenschaften,Einsatz,Produktion Methoden

R-S?tze Betriebsanweisung:

R37/38:Reizt die Atmungsorgane und die Haut.

R41:Gefahr ernster Augensch?den.

S-S?tze Betriebsanweisung:

S26:Bei Berührung mit den Augen sofort gründlich mit Wasser abspülen und Arzt konsultieren.

S39:Schutzbrille/Gesichtsschutz tragen.

Beschreibung

2,4,5-Trifluorophenylacetic acid is a fluorophenylacetic acid, which is a valuable intermediate for preparing various pharmacologically active compounds. In particular, trifluorophenylacetic acids are used to prepare inhibitors of the dipeptidyl peptidase-4 enzyme. These medicines are helpful in treating diabetes, in particular type 2 diabetes. One of these active ingredients is Sitagliptin, available commercially under the brand name Januvia, which uses 2,4,5-trifluorophenylacetic acid as a critical intermediate for its synthesis.

Chemische Eigenschaften

White to light brown solid

Verwenden

2,4,5-Trifluorobenzeneacetic Acid is used in the synthesis of EGFR/ErbB-2-kinase inhibitors. Also used in the synthesis of new imidazopyrazinone derivatives as potnetial dipeptidyl peptidase IV inhibitors.

Application

2,4,5-Trifluorophenylacetic acid is used to synthesize the intermediate of sitagliptin, a new drug for the treatment of type II diabetes. sitagliptin is a dipeptidyl peptidase-4 (DPP-4) inhibitor newly launched by Merck. It has good curative effect, small side effects, good safety and tolerance in treating type II diabetes.

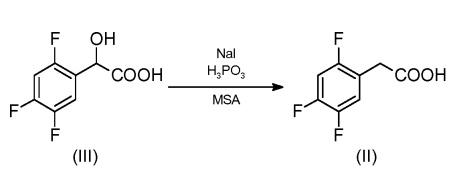

synthetische

synthesis of 2,4,5-trifluorophenylacetic acid: A 100 mL flask was charged 10.0 g of 2,4,5-trifluoromandelic acid, 23.9 g of H3PO3 (6 eq.), 0.73 g of Nal (0.1 eq.) and 0.47 g (0.10 eq.) of MSA. The obtained mixture was stirred at 95-105°C for 24 hrs. Once the conversion is completed (by HPLC; conversion > 99%, typically achieved after 24 hours), the mixture is cooled to room temperature, and 20 mL of methyl tert-butyl ether were added and then 20 mL of water where added. The obtained mixture was stirred for 5 min, then the organic layers were separated. Then 10 mL of methyl tert-butyl ether was added to the aqueous layers, stirred for 5 min, then the phase were separated. The organic layers were combined. The combined organic layers were concentrated under vacuum at 35°C, to provide crude 2,4,5-trifluorophenylacetic acid(TFPAA). To the obtained crude TFPAA was recrystallized from toluene, to obtain TFPAA, as a white crystals, 6.4 g, molar yield 69.5%, chemical purity of HPLC 99.47% A/A%

2,4,5-Trifluorophenylacetic acid Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte

Methyl 3-Oxo-4-(2,4,5-trifluorophenyl)butanoate

(Z)-Methyl 3-aMino-4-(2,4,5-trifluorophenyl)but-2-enoate

(R)-3-AMino-4-(2,4,5-trifluoro-phenyl)-butyric acid hydrochloride

Benzenebutanoicacid,b-aMino-2,4,5-trifluoro-,Methylester,(bR)-