Ethylvinylether Chemische Eigenschaften,Einsatz,Produktion Methoden

ERSCHEINUNGSBILD

FARBLOSE FLüSSIGKEIT MIT CHARAKTERISTISCHEM GERUCH.

PHYSIKALISCHE GEFAHREN

Die D?mpfe sind schwerer als Luft und k?nnen sich am Boden ausbreiten. Fernzündung m?glich. Flie?en, Schütten o.?. kann zu elektrostatischer Aufladung führen.

CHEMISCHE GEFAHREN

Bildung explosionsf?higer Peroxide. Polymerisiert leicht als Flüssigkeit oder Dampf. Reagiert sehr heftig mit Oxidationsmitteln und S?uren unter Feuer- und Explosionsgefahr.

ARBEITSPLATZGRENZWERTE

TLV nicht festgelegt (ACGIH 2005).

MAK nicht festgelegt (DFG 2005).

AUFNAHMEWEGE

Aufnahme in den K?rper durch Inhalation der D?mpfe.

INHALATIONSGEFAHREN

Beim Verdampfen bei 20°C kann sehr schnell eine gesundheitssch?dliche Kontamination der Luft eintreten.

WIRKUNGEN BEI KURZZEITEXPOSITION

WIRKUNGEN BEI KURZZEITEXPOSITION: M?glich sind Auswirkungen auf das Zentralnervensystem mit nachfolgender Bewusstlosigkeit.

LECKAGE

Ausgelaufene Flüssigkeit in abdichtbaren Beh?ltern sammeln. Reste mit Sand oder inertem Absorptionsmittel aufnehmen und an einen sicheren Ort bringen. NICHT in die Kanalisation spülen. Pers?nliche Schutzausrüstung: Umgebungsluftunabh?ngiges Atemschutzger?t.

R-S?tze Betriebsanweisung:

R12:Hochentzündlich.

R19:Kann explosionsf?hige Peroxide bilden.

R36/37/38:Reizt die Augen, die Atmungsorgane und die Haut.

S-S?tze Betriebsanweisung:

S16:Von Zündquellen fernhalten - Nicht rauchen.

S23:Gas/Rauch/Dampf/Aerosol nicht einatmen(geeignete Bezeichnung(en) vom Hersteller anzugeben).

S26:Bei Berührung mit den Augen sofort gründlich mit Wasser abspülen und Arzt konsultieren.

S3/7:Beh?lter dicht geschlossen halten und an einem kühlen Ort aufbewahren.

S33:Ma?nahmen gegen elektrostatische Aufladungen treffen.

S36:DE: Bei der Arbeit geeignete Schutzkleidung tragen.

Chemische Eigenschaften

Colorless liquid. Extremely reactive, can

be polymerized in liquid or vapor phase. Slightly soluble in water (0.9% by weight). Commercial

material contains inhibitor to prevent premature

polymerization. Often stored underground

to minimize vapor losses.

Verwenden

Ethyl vinyl ether is used in fragrances, lubricating oil additives and spices preparation. It acts as an intermediate for sulfadiazine. It finds application in pharmaceuticals as anesthetics and analgesics. Further, it is used as a solvent in organic synthesis.

synthetische

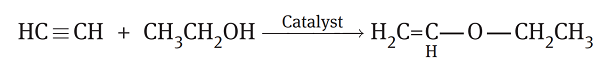

Ethyl vinyl ether (EVE) can be prepared by reacting acetylene with absolute ethanol in the presence of an alkali catalyst. The most commonly used catalyst for vinylation is an alkali metal hydroxide or an alkali metal alkoxide.

In China, three processes for the manufacture of EVE using the acetylene route were used:

A continuous process with a homogeneous catalyst under high pressure. The advantages of this process are fast reaction rate and high conversion, but the disadvantages include the requirement of high standard equipment, large energy consumption, and easy safety issues.

A process with a solid catalyst (heterogeneous catalyst) under atmospheric pressure is relatively simple in product separation and refining compared with a process with a homogeneous catalyst under high pressure. However, it has the disadvantages of low output, the short service life of catalyst (about 110 h), and a high requirement on the specification of carrier lime.

A process with a homogeneous catalyst under atmospheric pressure has the advantages of high output and good safety but disadvantages of low conversion.

In the process with solid catalyst under atmospheric pressure, acetylene, and ethanol vapor were introduced into a fixed-bed reactor, and the vinylation reaction was carried out at a temperature as high as about 180 °C. EVE was produced with a concentration of about 70% in the outlet gas stream from the reactor. The fixed-bed reactor was charged with 4–5 mesh catalyst particles of potassium hydroxide supported on lime.

Allgemeine Beschreibung

A clear colorless low-boiling liquid (35-36°C) with an ether-like odor. Flash point below -50°F. May polymerize exothermically if heated or contaminated. If polymerization takes place inside a container, the container may rupture violently. Less dense than water and slightly soluble in water. Hence floats on water. Vapors are heavier than air.

Air & Water Reaktionen

Highly flammable. Slightly soluble in water. Tends to form explosively unstable peroxides when exposed to oxygen.

Reaktivit?t anzeigen

Ethyl vinyl ether is a very dangerous fire and explosion hazard when exposed to heat or flame. Undergoes autooxidation with formation of peroxides in the air. Can react vigorously with oxidizing materials. Undergoes explosive polymerization in contact with methanesulfonic acid [Eaton, P. E. et al., J. Org. Chem., 1972, 37, p. 1947].

Hazard

Carcinogen.

Health Hazard

INHALATION OR INGESTION: Excitement followed by unconsciousness and respiratory paralysis. CNS depression. EYES: May cause irritation and transient injury to cornea. SKIN: Prolonged contact can cause tissue defatting and dehydration leading to dermatitis.

Brandgefahr

Behavior in Fire: Explosive hazard

Sicherheitsprofil

Mddly toxic by

ingestion. Mutation data reported. A skin

irritant. A very dangerous fire and explosion

hazard when exposed to heat or flame; can

react vigorously with oxidizing materials. To

fight fire, use alcohol foam, foam, CO2, dry

chemical. Explosive polymerization is

catalyzed by methane sulfonic acid. When

heated to decomposition it emits acrid

smoke and irritating fumes. See also

ETHERS.

Synthese

Ethyl vinyl ether is synthesized by bubbling Acetylene through Ethylalcohol in presence of Sodium ethoxide.

l?uterung methode

It usually contains polymerization inhibitors (usually amines, e.g. triethanolamine) which can be removed by fractional distillation. Redistil it from sodium. [Beilstein 1 IV 2049.] LACHRYMATORY.

Ethylvinylether Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte