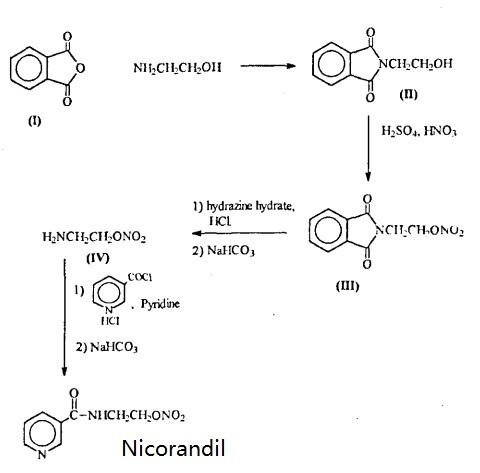

Nicorandil synthesis

- Product Name:Nicorandil

- CAS Number:65141-46-0

- Molecular formula:C8H9N3O4

- Molecular Weight:211.17

Nicorandil was synthesized from 2-aminoethanol by a four step process. In order to protect the amino group during nitration, 2-aminoethanol was first treated with phthalic anhydride. The amide formed was then nitrated using a nitrating mixture and was subsequently deprotected by reacting with hydrazine hydrate. The 2- nitroxyethylamine obtained was condensed with nicotinoyl chloride in pyridine. Treatment with aqueous sodium bicarbonate solution gave nicorandil as free base.

6265-73-2

125 suppliers

$89.00/100mg

65141-46-0

430 suppliers

$5.00/50mg

Yield:65141-46-0 85.9%

Reaction Conditions:

with nitric acid;propionic acid;propionic acid anhydride at 0 - 30; for 3.5 h;Temperature;

Steps:

1; 2 Example 2. Preparation of Nicorandil

Add 8.36g (90.264mmol) of 68% dilute nitric acid to a 100ml three-neck reaction flask, lower the temperature to 0 10 in an ice bath, weigh 20.00g propionic acid and 15.00g propionic anhydride into two constant pressure dropping funnels Slowly add dropwise to the reaction system, the system has a phenomenon of heat generation, control the temperature of the reaction system at 0 ~ 5 , dropwise addition is completed in about 15 minutes, keep stirring for 1.5 hours. Weigh 5.00g (30.088mmol) N- (2- hydroxyethyl) nicotinamide Add to the reaction system, remove the ice bath, return to 20 ~ 30 , stir the reaction for 3.5 hours, liquid phase monitoring of raw material remaining less than 0.5%. Stop the reaction, pour the reaction solution into 50ml of 12% dilute ammonia water and disperse and stir, a large amount of white solid precipitates, lower the temperature to 0-5 ° C, stir and crystallize, filter, and dry under reduced pressure at 45 ° C for 10 hours 3.70 g of white crystalline powder was obtained, yield: 85.9%.

References:

Beijing Wobang Pharmaceutical Technology Co., Ltd.;Zhang Weifeng;Wang Lei CN110845403, 2020, A Location in patent:Paragraph 0056-0059

40055-37-6

93 suppliers

$97.00/100mg

110-46-3

281 suppliers

$10.00/10g

65141-46-0

430 suppliers

$5.00/50mg

20260-53-1

202 suppliers

$16.00/5g

4665-58-1

10 suppliers

inquiry

65141-46-0

430 suppliers

$5.00/50mg

540-80-7

372 suppliers

$29.00/25 g

40055-37-6

93 suppliers

$97.00/100mg

65141-46-0

430 suppliers

$5.00/50mg

40055-37-6

93 suppliers

$97.00/100mg

65141-46-0

430 suppliers

$5.00/50mg