Ruthenium synthesis

- Product Name:Ruthenium

- CAS Number:7440-18-8

- Molecular formula:Ru

- Molecular Weight:101.07

The element is separated from the other platinum metals by a sequence involving treatment with aqua regia (separation of insoluble osmium, rhodium, ruthenium, and iridium), fusion with sodium bisulfate (with which rhodium reacts), and fusion with sodium peroxide (dissolution of osmium and ruthenium). The resulting solution of ruthenate and osmate is treated with ethanol to precipitate ruthenium dioxide. The ruthenium dioxide is purified by treatment with hydrochloric acid and chlorine and reduced with hydrogen gas to pure metal.

Ruthenium is recovered from exhausted catalytic converters or, in a similar manner, from the waste produced during platinum and nickel ore processing.

![Ruthenium, [(1,2,3,4,5,6-η)-methylbenzene][(1,2,4,5-η)-1-methyl-1,4-cyclohexadiene]-](/CAS/20211123/GIF/1033977-31-9.gif)

1033977-31-9

0 suppliers

inquiry

7440-18-8

350 suppliers

$29.12/5G

Yield:-

Reaction Conditions:

at 150 - 250; under 0.5 Torr;

Steps:

Ru(l-methyl-cyclohexa-l,4-diene)(toluene) is a light yellow precursor which is liquid at 2O0C. Pure ruthenium films were deposited from temperatures above 1500C using (1- methyl-cyclohexa-l,4-diene)(toluene) ruthenium. The liquid precursor was stored in a bubbler and the vapors were delivered to a hot-wall reactor by a bubbling method. An inert gas, helium

References:

WO2008/78296,2008,A1 Location in patent:Page/Page column 11-12

15243-33-1

199 suppliers

$28.00/250mg

7440-18-8

350 suppliers

$29.12/5G

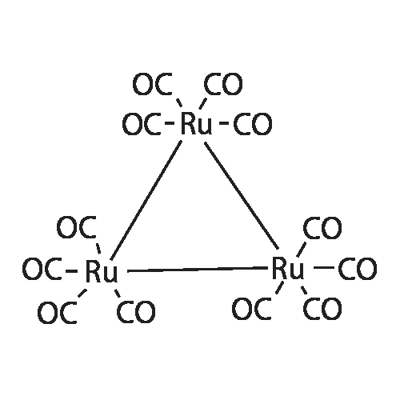

42516-72-3

5 suppliers

inquiry

7440-18-8

350 suppliers

$29.12/5G

10049-08-8

288 suppliers

$15.00/1g

7440-18-8

350 suppliers

$29.12/5G

41756-81-4

0 suppliers

inquiry

7440-18-8

350 suppliers

$29.12/5G