Maltitol synthesis

- Product Name:Maltitol

- CAS Number:585-88-6

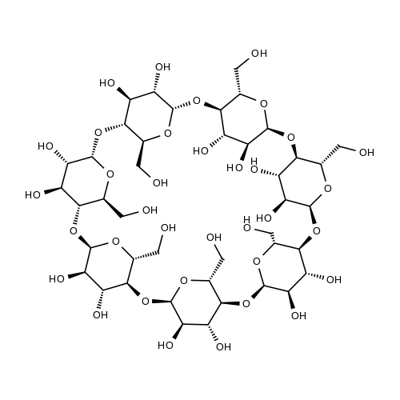

- Molecular formula:C12H24O11

- Molecular Weight:344.31

69-79-4

336 suppliers

$5.00/1g

585-88-6

498 suppliers

$6.00/25g

Yield:-

Reaction Conditions:

with hydrogen in water at 99.84; under 30003 Torr; for 4 h;Autoclave;Reagent/catalyst;

Steps:

2.3. Catalytic performances test

General procedure: The liquid-phase hydrogenation of sugar was performed at 4.0 MPaof H2 pressure and 373 K in a 200-mL stainless steel autoclave with aTeflon tube to avoid metal contamination, in which 0.5 g of Ni catalystand a sugar aqueous solution (10 wt.% in 50 mL H2O) were well mixed.According to the drop of the H2 pressure in the autoclave within 10min, both the specific activity (the H2 uptake rate per gram of Ni, RHm,mmol h-1 gNi-1) and the intrinsic activity (the H2 uptake rate per m2 ofNi, RHS, mmol h-1 mNi-2) were calculated by using the ideal gasequation. The reaction mixture was sampled at intervals for productanalysis through a liquid-phase chromatograph (Agilent 1200)equipped with a carbohydrate column (Shodex, SC1011) and a refractiveindex detector at 333 K with water as movable phase at 0.50mL min-1. Preliminary kinetic studies revealed that there was a plateauin the dependency of the reaction initial rate upon the stirring rateabove 1000 rpm and that the reaction initial rate varied linearly withcatalyst amount from 0.1 to 1.0 g, indicating that the stirring rate of1200 rpm was high enough that the hydrogenation rates were independentof mass transfer. After cooling to room temperature at theend of the reaction, the catalyst was separated by centrifugation andwashed with deionized water for further characterizations and applications.In order to determine the catalyst durability, the used catalystwas centrifuged and washed thoroughly with distilled water after eachrun of the reaction. Then, the used catalyst was reused with freshcharge of sugar for subsequent recycle runs under same reaction conditions.

References:

Yong, Yang;Huajun, Gu;Qingxiao, Zhang;Fang, Zhang;Hui, Li [Catalysis Today,2021,vol. 365,p. 282 - 290]