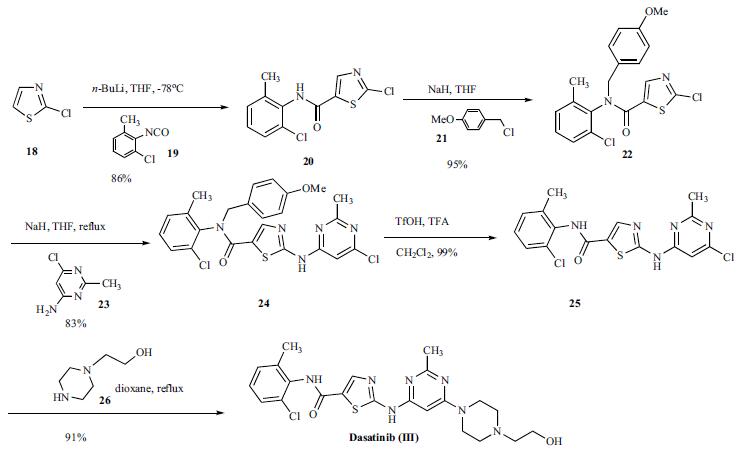

Dasatinib synthesis

- Product Name:Dasatinib

- CAS Number:302962-49-8

- Molecular formula:C22H26ClN7O2S

- Molecular Weight:488.01

103-76-4

504 suppliers

$6.00/25g

![N-(2-Chloro-6-methylphenyl)-2-[(6-chloro-2-methyl-4-pyrimidinyl)amino]-5-thiazolecarboxamide](/CAS/GIF/302964-08-5.gif)

302964-08-5

292 suppliers

$7.00/250mg

302962-49-8

508 suppliers

$9.00/50mg

Yield:302962-49-8 97%

Reaction Conditions:

with tetrabutylammomium bromide in acetonitrile at 30 - 80;

Steps:

2 Preparation of Dasatinib Monohydrate

200 ml of acetonitrile was taken in RB flask and 10.0 g of 2-((6-chloro-2-methylpyrimidin-4-yl)amino)-N-(2-chloro-6-methylphenyl)thiazole-5-carboxamide (Formula I), 19.8 g of 1-(2-Hydroxyethyl)piperazine (Formula II), 12.85 g of triethyl amine and 10.0 g of TBAB were charged into it. The reaction mass was stirred for 10-15 mins at 30-35° C. and then heated to 80° C. and stirred for 20-22 h. The completion of reaction was checked with Thin Layer Chromatography (TLC) and 300 mL of water was slowly charged. The reaction mass was stirred for 45 mins at 80° C. and then cooled to 30-35° C. and further stirred for 1.5 hrs. The reaction mass was filtered, washed with 20 mL water and suck dried for 10-15 min at RT. The wet compound was unloaded and air dried for 30 mins at 30-35° C. The material was loaded to a vacuum tray drier at 30-35° C. and vacuum was applied. The material was dried at 30-35° C. for 1 h and slowly dryer temperature was raised to 50-55° C. where drying was carried out for 8-10 hrs. The solid product obtained was then cooled to 30-35° C. and vacuum was released to obtain 12.5 g of the title compound. [0073] Yield-97% HPLC Purity-99.42%

References:

US2015/57446,2015,A1 Location in patent:Page/Page column 0072; 0073

103-76-4

504 suppliers

$6.00/25g

1780-26-3

468 suppliers

$10.00/10g

302964-24-5

404 suppliers

$9.00/250mg

302962-49-8

508 suppliers

$9.00/50mg

1245157-85-0

32 suppliers

$1200.00/100mg

302962-49-8

508 suppliers

$9.00/50mg

![5-Thiazolecarboxamide, N-(2-chloro-6-methylphenyl)-2-[[2-methyl-6-[4-[2-(phenylmethoxy)ethyl]-1-piperazinyl]-4-pyrimidinyl]amino]-](/CAS/20210305/GIF/1245157-70-3.gif)

1245157-70-3

0 suppliers

inquiry

302962-49-8

508 suppliers

$9.00/50mg

![5-Thiazolecarboxamide, N-(2-chloro-6-methylphenyl)-2-[[2-methyl-6-[4-[2-[(methylthio)methoxy]ethyl]-1-piperazinyl]-4-pyrimidinyl]amino]-](/CAS/20210305/GIF/1245157-78-1.gif)

1245157-78-1

0 suppliers

inquiry

302962-49-8

508 suppliers

$9.00/50mg