|

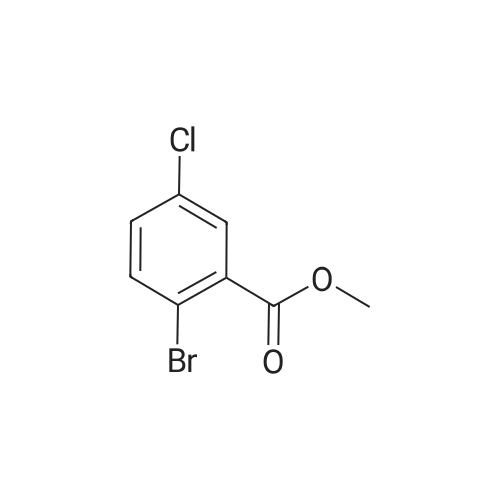

With sodium carbonate;tetrakis(triphenylphosphine) palladium(0); In ethanol; water; toluene; at 90℃; for 24h; |

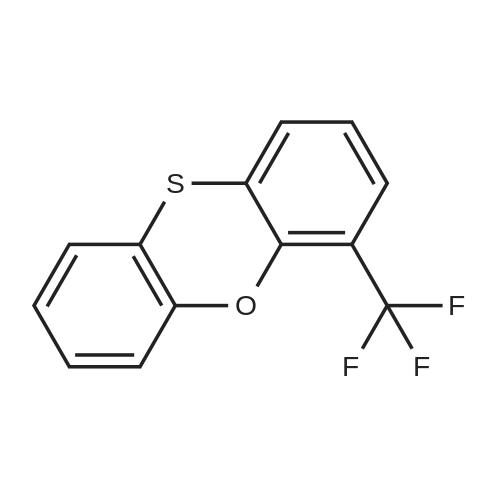

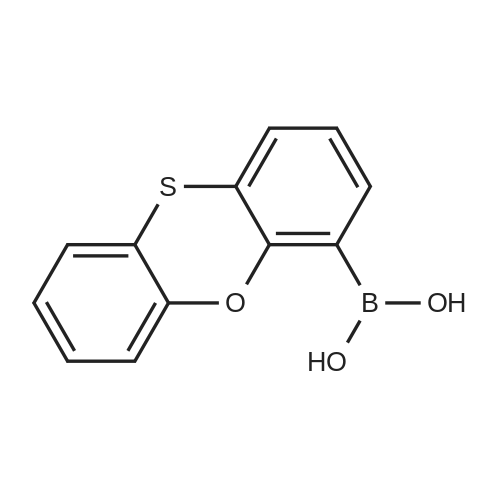

N,N-Diethyl-4-(4-phenoxathiinyl-4-piperidinylidenemethyl)- benzamide To a mixture of INTERMEDIATE 5 (0.202 g, 0.448 mmol), 4-PHENOXATHIINYL boronic acid (0.164 g, 0.672 MMOL), toluene (3.6 mL), ethanol (0.84 mL), and 2.0 M NA2CO3 (0.56 mL) in a N2 purged vial was added palladium tetrakistriphenylphosphine (0. 0518 g, 0.045 mmol). The resulting mixture was heated at 90 C for 24 h. The reaction was then concentrated in vacuo and the residue was diluted with water (4 mL) and CH2CI2 (4 mL). The layers were separated, and the aqueous phase was extracted with CH2CI2. The combined organic phases were dried over NA2SO4, filtered, and concentrated in vacuo. The crude product was purified by silica gel column chromatography eluting with 5: 1 CH2CI2 : EtOAc. The purified product was dissolved in CH2CI2 (10 mL) and trifluoroacetic acid (1 mL) was added. After 1.5 h, the reaction was concentrated in vacuo. The residue was LYOPHILIZED from CH3CN/H20 to give COMPOUND 3 as its trifluoroacetic acid salt (0.250 g, 95%) as a slightly yellow solid. Purity (HPLC): > 99% ; H NMR (400MHZ, CD30D) 8 1.06 (br t, J = 6.9 Hz, 3H), 1.22 (br t, J = 7.2 Hz, 3H), 2.44-2. 58 (m, 2H), 2.63-2. 73 (m, 1 H), 2.74-2. 83 (m, L H), 3.18-3. 28 (m, 5H), 3.31-3. 40 (m, 1 H), 3.52 (br q, J = 7.4 Hz, 2H), 6.75 (dd, J = 1.3 Hz, 7.9 Hz, IH), 6.98-7. 13 (m, 5H), 7.14-7. 17 (M, 1H), 7. 35 (s, 4H). |

|

With sodium carbonate;tetrakis(triphenylphosphine) palladium(0); In ethanol; toluene; at 90℃; for 24h; |

To a mixture of INTERMEDIATE 5 (0.202 g, 0.448 MMOL), 4-phenoxathiinyl boronic acid (0.164 g, 0.672 MMOL), toluene (3.6 mL), ethanol (0.84 mL), and 2.0 M NA2CO3 (0.56 mL) in a N2 purged vial was added palladium tetrakistriphenylphosphine (0. 0518 g, 0.045 MMOL). The resulting mixture was heated at 90 C for 24 h. The reaction was then CONCENTRATED IN VACUO and the residue was diluted with water (4 mL) and CH2CI2 (4 mL). The layers were separated, and the aqueous phase was extracted with CH2CI2. The combined organic phases were dried over NA2SO4, filtered, and CONCENTRATED IN VACUO. The crude product was purified by silica gel column chromatography eluting with 5: 1 CH2CI2 : EtOAc. The purified product was dissolved in CH2CI2 (10 mL) and trifluoroacetic acid (I mL) was added. After 1. 5 h, the reaction was CONCENTRATED IN VACUO. The residue was LYOPHILIZED from CH3CN/H20 to give COMPOUND 3 as its trifluoroacetic acid salt (0.250 g, 95%) as a slightly yellow solid. Purity (HPLC) : > 99% ; H NMR (400MHZ, CD30D) 8 1.06 (br t, J = 6.9 Hz, 3H), 1.22 (br t, J = 7.2 Hz, 3H), 2.44-2. 58 (m, 2H), 2.63-2. 73 (M, 1H), 2.74-2. 83 (m, 1 H), 3.18-3. 28 (m, 5H), 3. 31-3. 40 (m, 1H), 3.52 (br q, J = 7.4 Hz, 2H), 6.75 (dd, J = 1. 3 Hz, 7.9 Hz, 1H), 6.98-7. 13 (m, 5H), 7.14-7. 17 (m, 1 H), 7. 35 (s, 4H). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping