| Identification | Back Directory | [Name]

NONAFLUOROHEXYLTRIETHOXYSILANE | [CAS]

102390-98-7 | [Synonyms]

NONAFLUOROHEXYLTRIETHOXYSILANE

1H,1H,2H,2H-PERFLUOROHEXYLTRIETHOXYSILANE

1H,1H,2H,2H-Nonafluorohexyltriethoxysilane

Triethoxy(1H,1H,2H,2H-perfluorohexyl)silane

Triethoxy(1H,1H,2H,2H-nonafluorohexyl)silane

Silane,triethoxy(3,3,4,4,5,5,6,6,6-nonafluorohexyl)-

Triethoxy(1H,1H,2H,2H-nonafluorohexyl)silane

1H,1H,2H,2H-Nonafluorohexyltriethoxysilane

Triethoxy(1H,1H,2H,2H-perfluorohexyl)silane | [Molecular Formula]

C12H19F9O3Si | [MDL Number]

MFCD09954454 | [MOL File]

102390-98-7.mol | [Molecular Weight]

410.35 |

| Hazard Information | Back Directory | [Chemical Properties]

Colorless transparent liquid. | [Uses]

Nonafluorohexyltriethoxysilane is an organic silane, which can be used as an organic reagent. | [Application]

Main applications of Nonafluorohexyltriethoxysilane

1) Used as a coupling agent to increase the bonding strength of the fluorine-containing resin and the substrate.

2) Used to prepare water-proof, oil-proof and anti-fouling treatment agents, and it can be used in the protection of water-proof, anti-fouling and weathering of cultural relics, masonry, metal, wood, etc.

3) Used as a finishing agent to reduce the water holding capacity of natural fiber (wool, cotton, leather, etc.) products, and to improve surface water repellency and stain resistance.

4) Used as a water-repellent and antifouling treatment on the surface of glass. | [Production Methods]

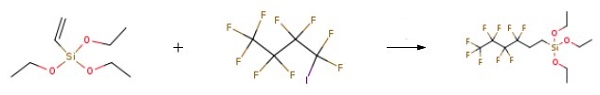

Nonafluorobutyl iodide (NFBI) and triethoxyvinylsilane (TEOVS) were fed into a three-necked flask equipped with a reflux condenser at a molar ratio of 1: 1.1 and then heated to 60 ℃ with stirring. When the internal temperature of the flask was sufficiently heated, azobisbutylnitrile (AIBN), a thermal decomposition radical initiator, was dissolved in an ether-based solvent. Then 0.5 ml/sec was dropped slowly into the stirred flask. After that, when the dropwise addition was completed, the external heating temperature was again set to 60 ℃ and stirred for 6 hours. After that, the internal temperature of the flask was lowered to room temperature (25 ℃), and tributyltin hydride (TBTH) was added to the flask at a rate of 1 ml/sec. After further stirring for 4 hours, distillation under reduced pressure at 1 Torr and 40 ° C yielded Nonafluorohexyltriethoxysilane in 75% yield.

|

|

|